© 2013 Drake Smith - Please do not

use or reproduce this elsewhere. Feel free to link to it

though.

Clutch

Work w/o BMW Special Tools

According to BMW and other shop

manuals, you need a couple of special tools to perform

maintenance on K bike clutches. In reality, you don't.

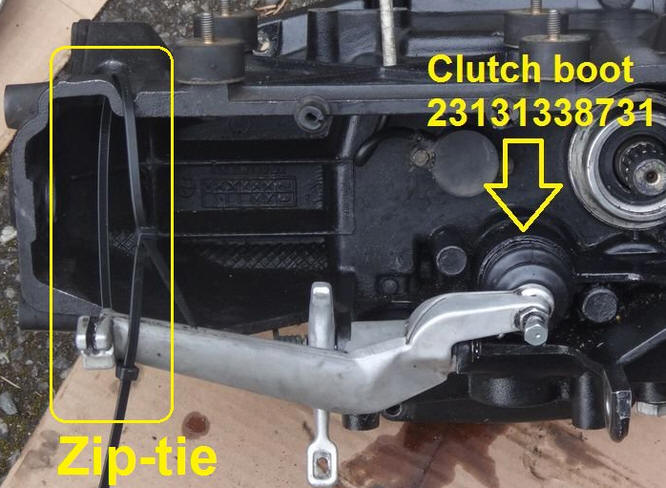

Saving The Clutch Boot

At the rear of the clutch pushrod

there is a rather expensive rubber boot - part 23131338731.

There is a spring inside of this

boot and if you fully release the clutch arm with an old

boot then the spring inside of the boot can tear it.

You can often avoid this if, when

the clutch cable is detached from the clutch arm, you use

zip-ties (or string/wire) to keep the clutch arm from fully

releasing.

Getting The Clutch Apart

Once the six bolts around the

perimeter of the clutch assembly have been removed, it is

often difficult to remove the rear piece to get the clutch

apart. You can carefully pry the clutch apart around the

outer edge using a 5 1/2" long mini pry bar/nail puller.

Examples are the Vaughan 222 or Titan 11505.

Be sure to get a 5 1/2" mini pry bar.

The heads on 7" pry bars are usually too large to fit in between

the bellhousing and clutch assembly.

BMW Holder - Part 112800

The purpose of this special tool is to

hold the clutch housing in place so the you can

remove/install the clutch nut without having it turn the

engine.

By inserting a block of wood into

the upper left corner between the bellhousing and one of the

clutch housing flanges, you can accomplish the same thing.

BMW Clutch Centering (Alignment) Tool - Part 212670

The purpose of this tool is to

center the clutch plate before retightening the six clutch

bolts so that the splines of the clutch plate are aligned

with transmission input shaft when the transmission is

re-installed.

You can buy aftermarket machined

aluminum clutch centering tools on eBay for about $25

shipped.

However, I developed my own

approach without the need for a special tool of any kind.

Namely, using the transmission itself as your centering

tool.

When you install the clutch

plate, tighten the six clutch bolts only enough to hold the

clutch plate in place by light friction so that it can still

move. Then feel around the edges and use your fingers to get

it as well centered as you can.

DO NOT

LUBE THE SPLINES YET. Only lube the splines upon

final installation of the transmission. Put the transmission in fifth

gear (makes turning the input splines via the output shaft

easier) and, without the pushrod in, temporarily install the

transmission, wiggling it around a little and using the

output shaft at the back to turn the input shaft

until it mates with the clutch plate.

Then push the

transmission all of the way on. The clutch plate is

now centered. Carefully pull the transmission STRAIGHT

back and then, once it is off, tighten the six clutch bolts.

(19 Nm)

Before lubing the splines and

inserting the clutch pushrod, install the transmission once

more to ensure that the clutch plate is properly centered

with the six clutch bolts tightened. Then remove the

transmission, insert the clutch pushrod, lube the

transmission input splines and execute the final transmission

installation. (16 Nm transmission to bellhousing)

© 2013 Drake Smith - Please do

not use or reproduce this elsewhere. Feel free to link

to it though.